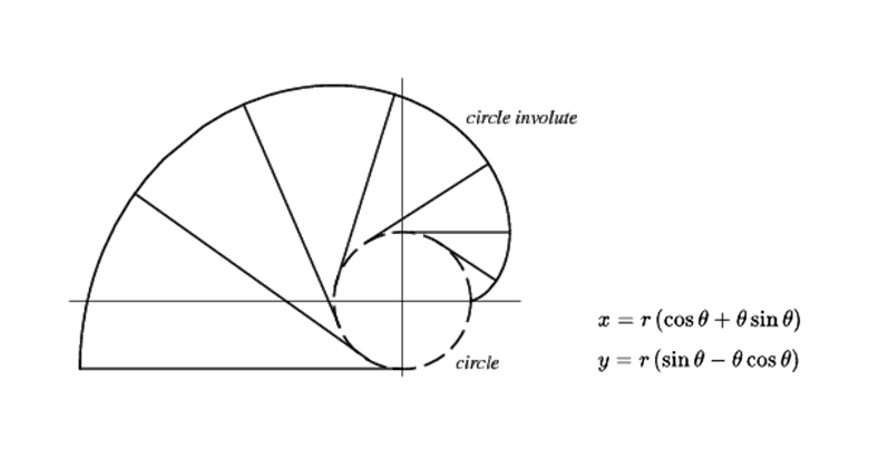

The involute gear profile is the most commonly used system for gearing today, with cycloidal gearing still used in the industry. In an involute gear, the profiles of the teeth are involutes of a circle. (The involute of a circle is the spiraling curve traced by the end of an imaginary taut string unwinding itself from that stationary circle called the base circle.)

In Cartesian coordinates the involute of a circle has the parametric equation:

Where r is the radius of the circle, and θ is the angle in radians (θ € R). The counterclockwise spiral is made with positive values of θ, and the clockwise spiral is made with the negative values of θ.

Compare to other teeth profiles the involute can not be affected by deviations of the axle distance of each gear. The positioning and run-out tolerances of the gear axles has a minor influence of the teeth sliding velocity. So the involute allows a constant torque and angle velocity transmission. This is its big advantage.

The teeth form has crucial importance for the correct function of a pair of gear. Early examples of gears date from the 4th century BC in China, which have been preserved at the Luoyang Museum of Henan Province, China. The earliest gears in Europe were circa AD 50 by Hero of Alexandria, but they can be traced back to the Greek mechanics of the Alexandrian school in the 3rd century BC and were greatly developed by the Greek polymath Archimedes (287–212 BC).

The Danish astronomer Ole Romer recommended around 1674 the epicycloid as teeth profile for gears. He probably discovered this during the build of his Jovilabium. The first mathematical analysis of this gear type was described by Philippe de La Hire around 1694 and was mainly applied in the clock mechanisms. In 1760 the Swiss mathematician Leonhard Euler recommended another teeth type: the involute gear was born.

The steam engine development during the industrial revolution in 18th century brought the needs to develop gear systems. Today there are a lot of gear types such as:

- Spur gears or straight-cut gears

- Helical or "dry fixed" gears

- Double helical gears and herringbone gears

- Bevel gears

- Spiral bevel gears

- Hypoid gears

- Crown gears or contrate gears

- Worm drive gears

- Rack and pinon

The common characteristic for all these gear types are the basic requirements for a gear tooth system. Their parameters are described in international standards and need to be considered for the design and development.

The calculation and definition of a gear tooth systems is very complex and need to be conducted by experts. Additional to the geometric requirements the designer needs to focus on the appropriate material, load conditions and manufacturing process.

The contact point between both teeth moves always along a line. This line gives the transmission force direction. (Involute profiles).